Pycnomètre: Ultrapyc 1200e, Quantachrome

The gas pycnometer measures the actual density of solid samples using an inert gas. The pycnometer does not affect the chemistry of the materials and allows measurements to be made with high precision (thanks to its many built-in expansion volume chambers).Features: – The gas pycnometer measures the actual density of solid samples using an inert gas. The pycnometer does not affect the chemistry of the materials and allows measurements to be made with high precision (thanks to its many built-in expansion volume chambers).Features: – The gas pycnometer measures the actual density of solid samples using an inert gas. The pycnometer does not affect the chemistry of the materials and allows measurements to be made with high precision (thanks to its many built-in expansion volume chambers).Features:

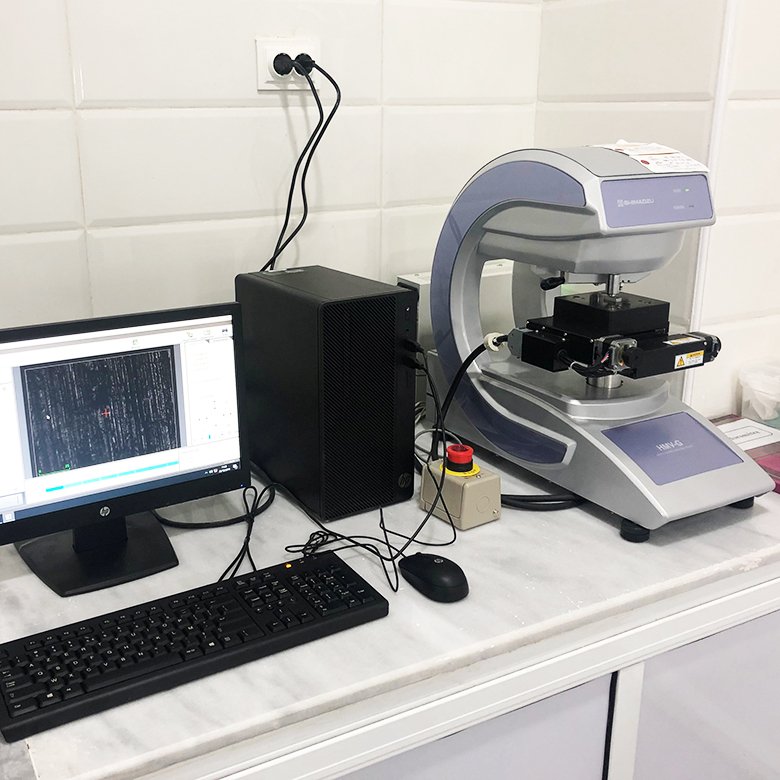

The microdurometer

Allows automatic micro-hardness tests to be carried out on a metal or ceramic sample. Equipped with a force sensor allows to choose any value between 98.7 mN and 19.61 N (HV0, 01 to HV2) with a resolution of 0.01 micron in compliance with the ISO 6507-1 standard .

La marque: SHIMADZU La Version: HMV-G-XY-S

Glow Discharge Optical Emission Spectroscopy

Allows automatic micro-hardness tests to be carried out on a metal or ceramic sample. Equipped with a force sensor allows to choose any value between 98.7 mN and 19.61 N (HV0, 01 to HV2) with a resolution of 0.01 micron in compliance with the ISO 6507-1 standard .

Fields of application: are very wide and include PV cells, PVD deposition, paints, galvanizing lines, nitriding, nuclear materials, oxides, ceramics, semiconductors, etc.The brand: HORIBA La Version: GD PROFILER 2

La BET

Fields of application: are very wide and include PV cells, PVD deposition, paints, galvanizing lines, nitriding, nuclear materials, oxides, ceramics, semiconductors, etc. – Fields of application: are very wide and include PV cells, PVD deposition, paints, galvanizing lines, nitriding, nuclear materials, oxides, ceramics, semiconductors, etc. – Fields of application: are very wide and include PV cells, PVD deposition, paints, galvanizing lines, nitriding, nuclear materials, oxides, ceramics, semiconductors, etc. – Nature of the samples to be analyzed: bulk or powder. For bulk samples, we have analysis cells of 6, 9 and 12 mm in diameter. Applications: pharmaceuticals, catalysts and filters, medical implants, cements, etc.

Brand: QUANTACHROME La Version: AUTOSORB iQ3

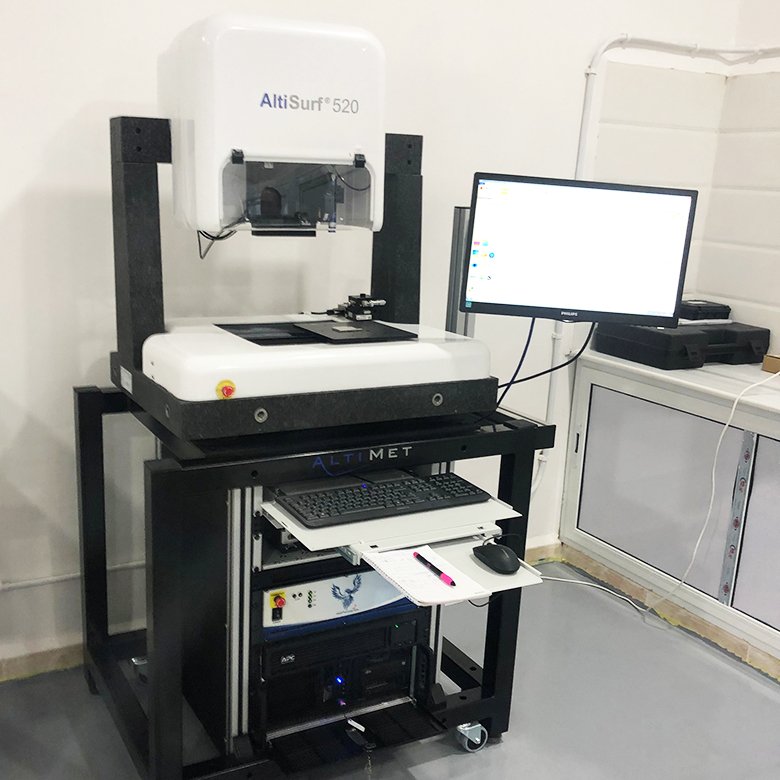

3D profilometer roughness meter

the Altisurf 520 is ideal for topographic analysis of large capacity surfaces (X, Y, Z (mm): 200 × 200 × 200mm) and has 2 types of contact measurement: inductive probe and micro force (Resolution 6nm) and 3 types without contact: 2 confocal chromatic probes with (100µm and 1mm) and an interferometry probe on the same sensor with a range of 90 µm (Resolution 0.5 µnm), Triangulated laser. And equipped with processing software that allows it to analyze roughness, tribology and topographic phenomena.

MEB-FEG: Quattro S

SEM FEG is a microscope capable of generating and collecting all available information from any type of sample material. It can be freely and simply switched between three vacuum modes, allowing the investigation of conductive, non-conductive, and high-vacuum mismatched materials.

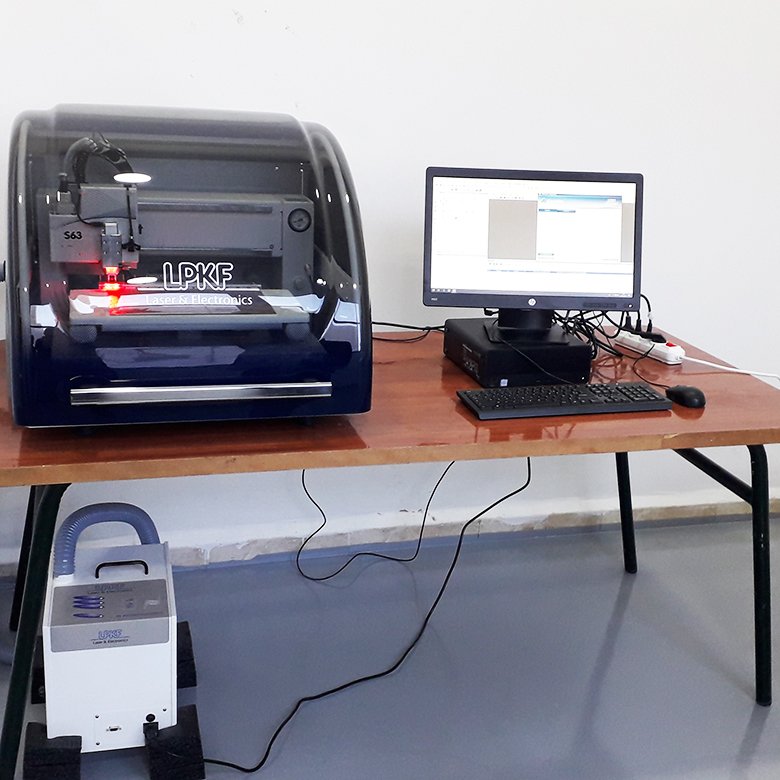

ProtoMat S63

It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures.

It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures.

It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures.

It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures.

It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures.

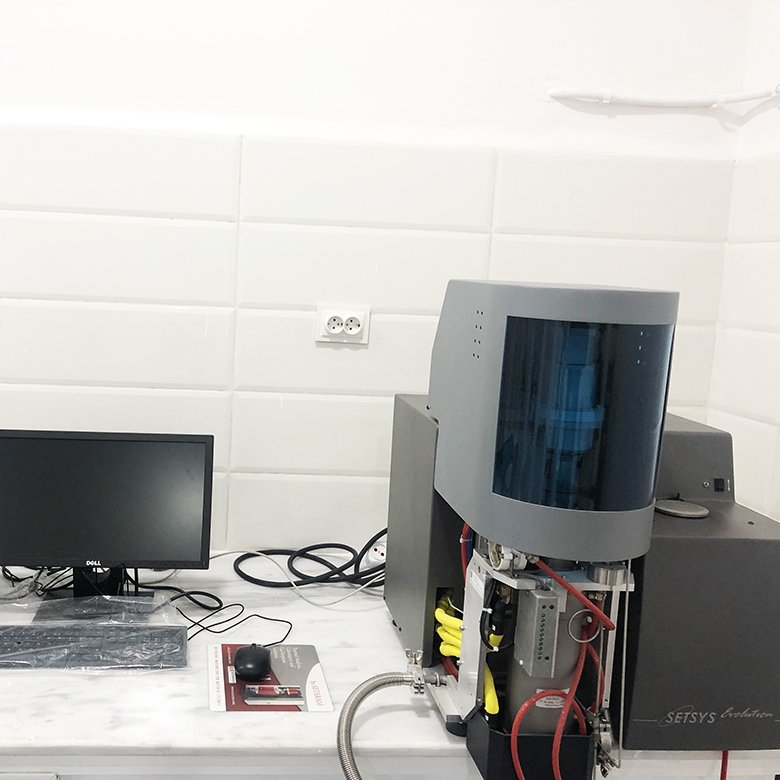

The quenching dilatometer is a thermal analysis technique allowing the determination of the parameters of the heat treatments of metallic alloys (particularly steels) necessary to obtain the crystalline structure corresponding to the required physical properties.

The quenching dilatometer is a thermal analysis technique allowing the determination of the parameters of the heat treatments of metallic alloys (particularly steels) necessary to obtain the crystalline structure corresponding to the required physical properties.

The quenching dilatometer is a thermal analysis technique allowing the determination of the parameters of the heat treatments of metallic alloys (particularly steels) necessary to obtain the crystalline structure corresponding to the required physical properties.

– The quenching dilatometer is a thermal analysis technique allowing the determination of the parameters of the heat treatments of metallic alloys (particularly steels) necessary to obtain the crystalline structure corresponding to the required physical properties. – Heating rate: from 0.01 to 100 ° C / min – Heating rate: from 0.01 to 100 ° C / min – Heating rate: from 0.01 to 100 ° C / min – The study of the thermal behavior (phase transformations) and the measurement of the expansion coefficients of metal and ceramic alloys.

The study of the thermal behavior (phase transformations) and the measurement of the expansion coefficients of metal and ceramic alloys.

The study of the thermal behavior (phase transformations) and the measurement of the expansion coefficients of metal and ceramic alloys.&D. The bi-axial testing machine is particularly well suited for testing specimens, for research purposes as well as for carrying out individual tests.

RHEOMETER MCR 502 BY ANTON BY

The MCR 502 rheometer from AntonPaar is designed to meet the highest demands of rheologists. All types or combinations of rheological tests are possible, both in oscillation mode and in rotation mode. The modularity of the system allows you to integrate a set of temperature devices and accessories for special applications into the rheometer. The innovative technologies of Toolmaster, TruGap, as well as T-Ready have become a real breakthrough in terms of simplifying work. TruRate, TruStrain and Axial Piezo drive technologies ensure control at all times during rheological testing.

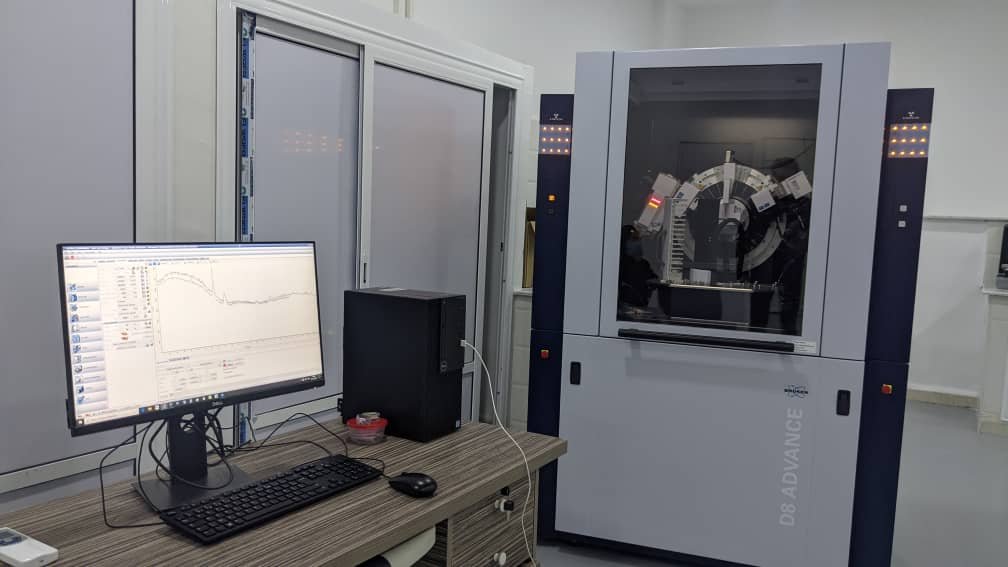

X-ray diffractometer

X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry.

Characteristics

X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry.

X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry.

X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry.

X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry.

X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry.

X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Microdiffraction optics to analyze different areas of the same sample.

Observe in situ structural and microstructural transformations as a function of sample temperature.La marque: USER La Version: D8 ADVANCE

X Fluorescence Spectrometer

Observe in situ structural and microstructural transformations as a function of sample temperature.

Characteristics : A Wavelength Dispersive X-ray Spectrometer (WDXRF) equipped with a standardless method. Possibility of mapping (determination of the spatial distribution of chemical elements).

Applications : A Wavelength Dispersive X-ray Spectrometer (WDXRF) equipped with a standardless method. Possibility of mapping (determination of the spatial distribution of chemical elements).… : A Wavelength Dispersive X-ray Spectrometer (WDXRF) equipped with a standardless method. Possibility of mapping (determination of the spatial distribution of chemical elements).

La marque: USER La Version: S8 TIGER

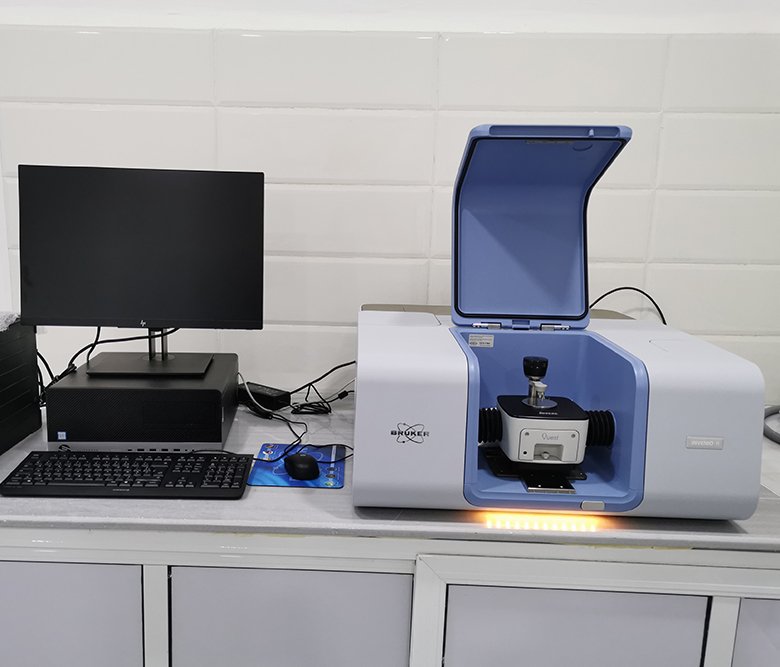

FTIR-ATR Infrared Spectrometer: Bruker

Fourier Transform Infrared (FTIR) spectroscopy is an effective physico-chemical characterization technique. This technique uses absorption, reflectance and transmission spectra in the infrared range to analyze the molecular bonds of solid, gaseous and liquid samples. FTIR technology based on the Fourier transform and the Michelson interferometer makes it possible to simultaneously collect spectral data over a wide spectrum, which produces a very high signal-to-noise ratio. This is a significant advantage over conventional dispersive infrared spectrometers. 5900-75 cm-1 without change of separator with a spectral resolution of 1 cm-1, the ATR accessory,

Simultaneous Thermal Analyzer (TGA / DSC): TGA / DSC 3+ 1600 °C, METTLER TOLEDO

This technique makes it possible to follow the variations of mass and heat flux as a function of temperature. It gives users the ability to analyze a wide variety of samples.

| ID | Equipment | Description | |

|---|---|---|---|

| Simultaneous Thermal Analyzer (TGA / DSC): TGA / DSC 3+ 1600 °C, METTLER TOLEDO | DescriptionThis technique makes it possible to follow the variations of mass and heat flux as a function of temperature. It gives users the ability to analyze a wide variety of samples. Characteristics: - Possibility of carrying out analyzes between 25°C and 1600°C in a controlled atmosphere (air, nitrogen or argon). - Heating rate: 0.1 to 100°C/min. - The balance: 5g measurement range with a resolution of 1µg. Crucibles available: small alumina and platinum crucibles (70 µL) and large alumina crucibles (600 and 900 µL). It is mainly used for: - determining the composition materials (purity), - study of the transition of glass and the degradation of rubber and polymeric and synthetic materials, - characterization of pharmaceutical products. - studies of reduction and oxidation reactions under controlled atmospheres (air, nitrogen, etc.). - study of phase transformations in metal alloys and ceramics. | ||

| La BET | he BET method is based on the adsorption of a gas (nitrogen) on the surface of a material. The quantity of adsorbed gas, at a given pressure, makes it possible to determine the specific surface, the volume, the size and the distribution of the pores as well as the energies of the adsorption and desorption reactions. Characteristics: - The measuring gas: nitrogen. - The maximum temperature of the degassing station is 400°C. - Nature of the samples to be analyzed: bulk or powder. For bulk samples, we have analysis cells of 6, 9 and 12 mm in diameter. Applications: pharmaceuticals, catalysts and filters, medical implants, cements, etc. | ||

| The microdurometer | allows automatic micro-hardness tests to be carried out on a metal or ceramic sample. Equipped with a force sensor allows to choose any value between 98.7 mN and 19.61 N (HV0, 01 to HV2) with a resolution of 0.01 micron in compliance with the ISO 6507-1 standard . | ||

| allows automatic micro-hardness tests to be carried out on a metal or ceramic sample. Equipped with a force sensor allows to choose any value between 98.7 mN and 19.61 N (HV0, 01 to HV2) with a resolution of 0.01 micron in compliance with the ISO 6507-1 standard . | allows automatic micro-hardness tests to be carried out on a metal or ceramic sample. Equipped with a force sensor allows to choose any value between 98.7 mN and 19.61 N (HV0, 01 to HV2) with a resolution of 0.01 micron in compliance with the ISO 6507-1 standard . Fields of application: are very wide and include PV cells, PVD deposition, paints, galvanizing lines, nitriding, nuclear materials, oxides, ceramics, semiconductors, etc. | ||

| Profilometer 3D roughness meter | the Altisurf 520 is ideal for topographic analysis of large capacity surfaces (X, Y, Z (mm): 200 × 200 × 200mm) and has 2 types of contact measurement: inductive probe and micro force (Resolution 6nm) and 3 types without contact: 2 confocal chromatic probes with (100µm and 1mm) and an interferometry probe on the same sensor with a range of 90 µm (Resolution 0.5 µnm), Triangulated laser. And equipped with processing software that allows it to analyze roughness, tribology and topographic phenomena. | ||

| Pycnomètre: Ultrapyc 1200e, Quantachrome | The gas pycnometer measures the actual density of solid samples using an inert gas. The pycnometer does not affect the chemistry of the materials and allows measurements to be made with high precision (thanks to its many built-in expansion volume chambers).Features: - The measurement gas: helium.- Sample volume : 0.1 - 135 cm3. Applications: The helium pycnometer is used to determine: the porosity and density of powders and bulk materials (metallic, ceramic and organic). This technique can be a complement to the BET technique. | ||

| MEB-FEG: Quattro S | SEM FEG is a microscope capable of generating and collecting all available information from any type of sample material. It can be freely and simply switched between three vacuum modes, allowing the investigation of conductive, non-conductive and high-vacuum incompatible materials: SEM FEG is a microscope capable of generating and collecting all available information from any type of sample material. It can be freely and simply switched between three vacuum modes, allowing the investigation of conductive, non-conductive and high-vacuum incompatible materials:<6 * 10-4 Pa) pour l'imagerie et la microanalyse d'échantillons conducteurs > SEM FEG is a microscope capable of generating and collecting all available information from any type of sample material. It can be freely and simply switched between three vacuum modes, allowing the investigation of conductive, non-conductive and high-vacuum incompatible materials: SEM FEG is a microscope capable of generating and collecting all available information from any type of sample material. It can be freely and simply switched between three vacuum modes, allowing the investigation of conductive, non-conductive and high-vacuum incompatible materials: SEM FEG is a microscope capable of generating and collecting all available information from any type of sample material. It can be freely and simply switched between three vacuum modes, allowing the investigation of conductive, non-conductive and high-vacuum incompatible materials: SEM FEG is a microscope capable of generating and collecting all available information from any type of sample material. It can be freely and simply switched between three vacuum modes, allowing the investigation of conductive, non-conductive and high-vacuum incompatible materials: - The EBSD system | ||

| ProtoMat S63 | - The EBSD system It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures. It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures. It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures. It is the ideal system for virtually any in-house prototyping application where speed and safety are crucial. It is also ideal for multilayer and RF applications. The high rotational speed guarantees the fine structures down to 100 μm required by many modern applications. The ProtoMat S63 masters the machining of 2.5D materials and has a higher spindle speed of 60,000 rpm. Which also makes it suitable for drilling test adapters and producing enclosures. | ||

| TMA / DILATOMETRIE: SETSYS Evolution TMA 16/18, SETARAM | The quenching dilatometer is a thermal analysis technique allowing the determination of the parameters of the heat treatments of metallic alloys (particularly steels) necessary to obtain the crystalline structure corresponding to the required physical properties. The quenching dilatometer is a thermal analysis technique allowing the determination of the parameters of the heat treatments of metallic alloys (particularly steels) necessary to obtain the crystalline structure corresponding to the required physical properties. - Temperature range: from room temperature to 1600°C - Heating rate: from 0.01 to 100°C/min - Measurements can be performed under a variable load between 0.5 and 35 cN - Measurements can be carried out, under vacuum, air or controlled atmospheres (nitrogen or argon).- Shape of the samples: parallel or cylindrical in shape and from 0.5 to 20 mm in length. The TMA dilatometer is generally used to measure dimensional variations of solid materials. It essentially allows to: -Study the softening, the glass transition, the degradation, the reticulation under different constraints of polymeric and ceramic materials, - The study of the thermal behavior (phase transformations) and the measurement of the expansion coefficients of the alloys metals and ceramics. | ||

| X-ray diffractometer | X-ray diffraction allows the detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry. Characteristics X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry. X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry. X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry. X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry. X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry. X-ray diffraction allows detailed non-destructive analysis of any material (in the form of masses, powders or thin layers), from the field of fundamental research to that of quality control in industry. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Microdiffraction optics to analyze different areas of the same sample. Observe in situ structural and microstructural transformations as a function of sample temperature. | ||

| X Fluorescence Spectrometer | Observe in situ structural and microstructural transformations as a function of sample temperature. | ||

| RHEOMETER MCR 502 BY ANTON BY | The MCR 502 rheometer from AntonPaar is designed to meet the highest demands of rheologists. All types or combinations of rheological tests are possible, both in oscillation mode and in rotation mode. The modularity of the system allows you to integrate a set of temperature devices and accessories for special applications into the rheometer. The innovative technologies of Toolmaster, TruGap, as well as T-Ready have become a real breakthrough in terms of simplifying work. TruRate, TruStrain and Axial Piezo drive technologies ensure control at all times during rheological testing. | ||

| FTIR-ATR Infrared Spectrometer: Bruker | Fourier Transform Infrared (FTIR) spectroscopy is an effective physico-chemical characterization technique. This technique uses absorption, reflectance and transmission spectra in the infrared range to analyze the molecular bonds of solid, gaseous and liquid samples. FTIR technology based on the Fourier transform and the Michelson interferometer makes it possible to simultaneously collect spectral data over a wide spectrum, which produces a very high signal-to-noise ratio. This is a significant advantage over conventional dispersive infrared spectrometers. 5900-75 cm-1 without change of separator with a spectral resolution of 1 cm-1, the ATR accessory, | ||

| To carry out mechanical tests (traction, compression, shear, bending and bending (three points and four points) on various types of materials: metals, polymers, ceramics and composites. | |||