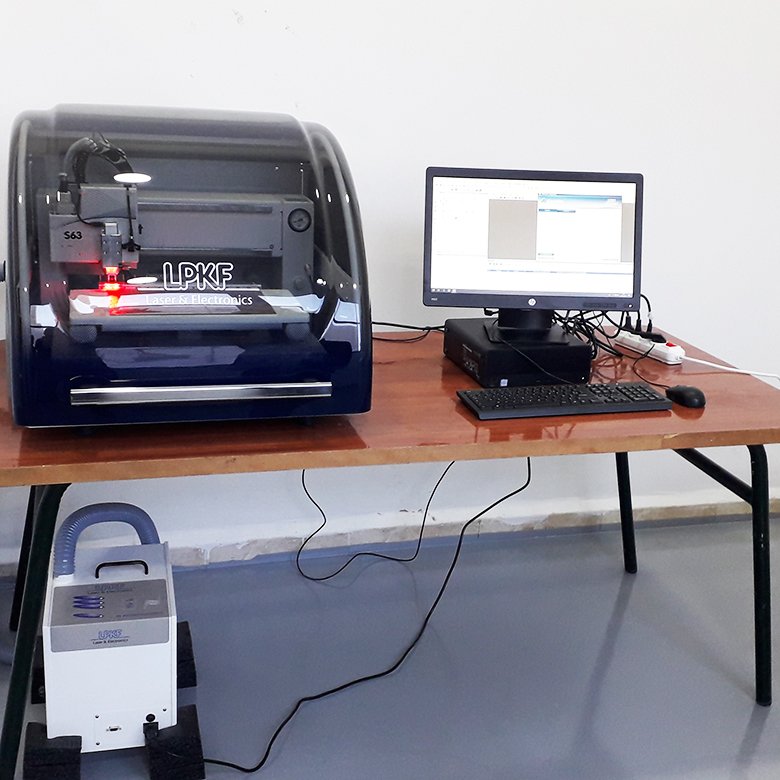

It focuses on describing the elaboration-microstructure-properties relationships of the materials produced and treated as well as tests on the manufactured parts. This section is very useful because it will make it possible to understand and verify the properties obtained, following the various treatments for a better practical application and to evaluate and control the materials used in the manufacture of the various devices and parts; it will take charge of all the necessary analyzes and tests required by the other sections. It will also have to ensure the maintenance and repair of broken down devices.

The Analysis, Evaluation and Maintenance section will have the following equipment:

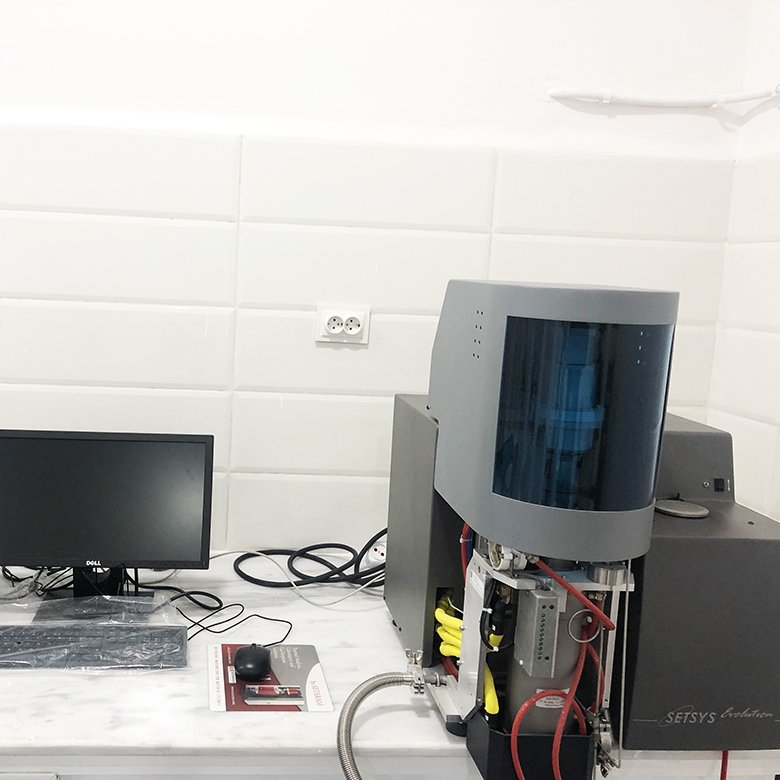

- thermal analysis equipment, namely:

- a differential dilatometer (TMA),

- a DSC/ATD/ATG 1400°C and a quenching dilatometer

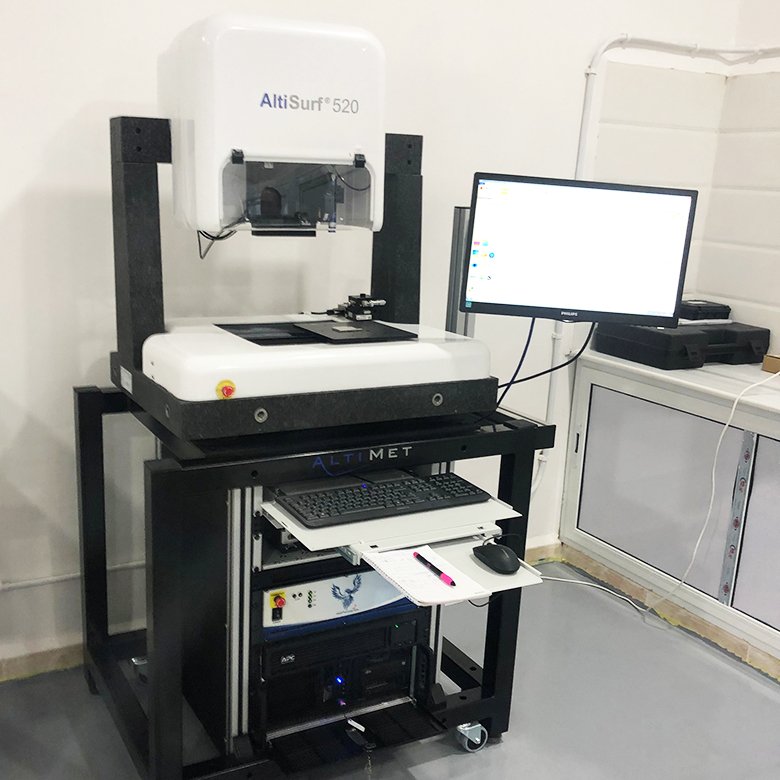

- Mechanical characterization equipment such as the Biaxial Fatigue Machine, the Universal Mechanical Testing Machine and a micro-hardness tester.

- MEB / FEG.

- Glow discharge spectrometer

- Radio-Frequency (GDOES)

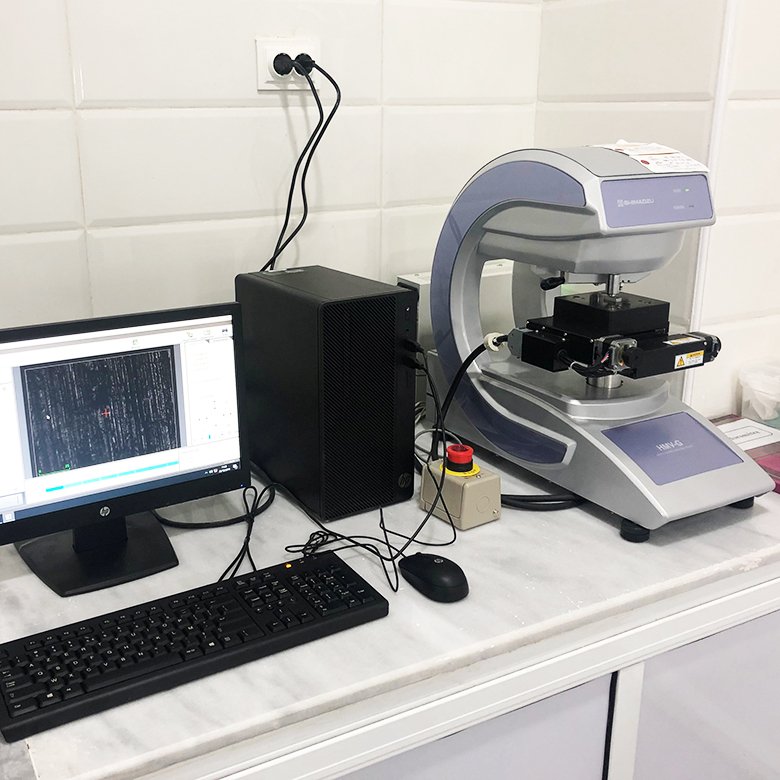

- X-ray diffractometer

- Fluorescence X.

- FTIR ATR Raman Infrared Spectrometer.

- Rheometer.

- To carry out mechanical tests (traction, compression, shear, bending and bending (three points and four points) on various types of materials: metals, polymers, ceramics and composites.

- Potentiostat-Galvanostat ..

- Quenching dilatometer.