Atomic force microscope (Flex AFM-Nanosurf)

This is a very high resolution (SPM) scanning probe microscopy, with a demonstrated resolution of the order of fractions of a nanometer. Flexafm can perform static force, phase imaging, dynamic force, lateral force, magnetic force microscopy, lithography and electrochemical nanomanipulation AFM (EC-AFM).

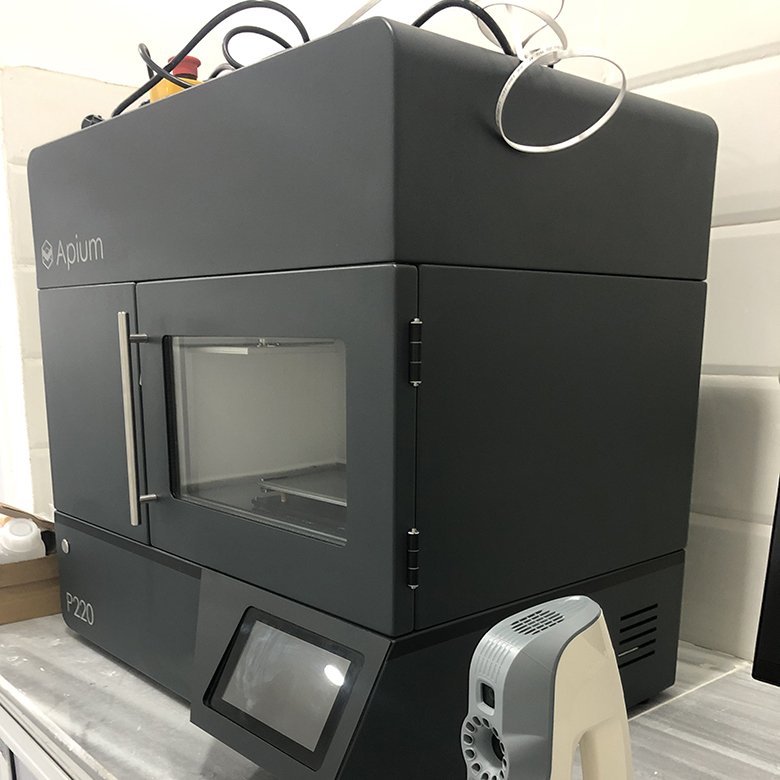

Thermoplastic printer with scanner

The industrial 3D printer, APIUM P220, works according to the FDM technique and specially dedicated to the manufacture of complex architectural parts, based on high-end thermoplastic materials: PEEK, Carbon PEEK (30%), PVDF, POM-C, PP . Main features of the P220 • Adaptive heating (up to 180 ° C) • High temperature of the 3D printing plate (up to 160 ° C) and of the nozzle (up to 540 ° C): allows printing 3D of the required engineering materials (PEEK, PEI, metals, composites, etc.).

MACHINE-DUSINAGE-5AXES-ULTRASONIC-50

With ultrasonic technology integration to reduce cutting resistance, longer tool life and improved surface finishes up to Ra < 0, 1 µm. The movements along the X.Y.Z axes are 650x520x475 mm, the spindle speed is 20,000 rpm with a swivel table and equipped with a tool changer with 30 places.

3d ceramic printer

Allows flexible preparation of very complex and precise structures that are difficult to achieve using traditional manufacturing methods. This CERAMAKER 900 hybrid printer (the first installed in Africa and the Arab countries,) can print several materials at the same time and offers a printing plate of 300 mm x 300 mm x 100 mm, interchangeable with one of 300 x 200 and one of 300 x 100. It uses the principle of laser stereolithography (LAS). The formed part has a very appreciable mechanical resistance to handle; The fields of use are: Aeronautics, Industry, Biomedical, Luxury … ..

300 ton hydraulic press

The RM-300 PROFI PRESS hydraulic arch press is equipped with a low table and a top table with two "T" grooves, four side guide pins are installed to ensure perfect alignment of the top table and a motorized hydraulic unit two-speed.

Waterjet cutting machine

The water jet cutting machine uses a hyperbaric water jet for machining technical parts and can cut materials such as metal (aluminum, stainless steel, steel, etc.), granite, PVC, glass , rubber and others. The cuts are made with pure water for soft materials and with the addition of an abrasive for harder materials. The cutting diameter of less than one millimeter allows optimization of the quantities of material used. This technique, intended for professionals in different sectors of activity, makes it possible to cut almost any material in any thickness. This industrial machine is practically used for high precision cutting.

Tour- 3 axes

Ensures complete machining on 6 sides of parts for a turning diameter of up to 400 mm and a length between centers of 800 mm.

| ID | Equipment | Description | Price | |

|---|---|---|---|---|

| CERAMIC 3D PRINTER: CERAMAKER900 | Enables flexible preparation of very complex and precise structures that are difficult to achieve using traditional fabrication methods. This CERAMAKER 900 hybrid printer (the first to be installed in Africa and Arab countries) can print several materials at the same time and offers a printing plate of 300 mm x 300 mm x 100 mm, interchangeable with one of 300 x 200 and one 300 x 100. It uses the principle of laser stereolithography (LAS). The formed part has a very appreciable mechanical resistance to handle; The areas of use are: Aeronautics, Industry, Biomedical, Luxury ... .. | |||

| THERMOPLASTIC 3D PRINTER: APIUM220 with SCANNER | The industrial 3D printer, APIUM P220, works according to the FDM technique and is specially dedicated to the manufacture of complex architectural parts, based on high-end thermoplastic materials: PEEK, Carbon PEEK (30%), PVDF, POM-C, PP . Main features of the P220 • Adaptive heating (up to 180°C) • High temperature of the 3D printing bed (up to 160°C) and the nozzle (up to 540°C): enables printing 3D of required engineering materials (PEEK, PEI, metals, composites, etc.). | |||

| "Artec Eva scanner" | "Ce scanner est avec lumière structurée, il a les caractéristiques suivantes : - Dimension de la surface numérisée 530 x 370 mm³ - Résolution égale ou supérieure à 0,5 mm³ - Alimentation et câble USB" | |||

| "Machine de découpe au jet d’eau" | The water jet cutting machine uses a hyperbaric water jet for machining technical parts and can cut materials such as metal (aluminum, stainless steel, steel, etc.), granite, PVC, glass , rubber and others. The cuts are made with pure water for soft materials and with the addition of an abrasive for harder materials. The cutting diameter of less than one millimeter allows optimization of the quantities of material used. This technique, intended for professionals in different sectors of activity, makes it possible to cut almost any material in any thickness. This industrial machine is practically used for high precision cutting. | |||

| Tour- 3 axes | Ensures complete machining on 6 sides of parts for a turning diameter of up to 400 mm and a length between centers of 800 mm. | |||

| The ultrasonic 5-axis machining center | With ultrasonic technology integration to reduce cutting resistance, longer tool life and improved surface finishes up to Ra < 0,1 µm.les déplacements suivant les axes X.Y.Z sont de 650x520x475 mm, la vitesse de la broche est de 20000 tr/mn avec table pivotante et Muni d’un changeur d'outil avec 30 places. | |||

| 300 ton hydraulic press | With ultrasonic technology integration to reduce cutting resistance, longer tool life and improved surface finishes up to Ra | |||

| Atomic force microscope (Flex AFM-Nanosurf) | This is a very high resolution (SPM) scanning probe microscopy, with a demonstrated resolution of the order of fractions of a nanometer. Flexafm can perform static force, phase imaging, dynamic force, lateral force, magnetic force microscopy, lithography and electrochemical nanomanipulation AFM (EC-AFM). | |||

| With ultrasonic technology integration to reduce cutting resistance, longer tool life and improved surface finishes up to Ra | With ultrasonic technology integration to reduce cutting resistance, longer tool life and improved surface finishes up to Ra | |||